Bullet Resistance Standards

The following article is provided as a technical reference to assist architects and security professionals in interpreting bullet-resistance standards and/or evaluating the vulnerability of existing barrier materials.

The most useful reference for specifying design and construction of bullet-resistant structural walls is U.S. Department of Defense UFC 4-023-07 (Design to Resist Direct Fire Weapons Effects).[1] UFC 4-023-07 Table 5-3 provides guidance on the construction of structural barriers to resist four levels of ballistic threat. If a safe room designer uses 7.62x51mm NATO ammunition (or lesser caliber such as 5.56mm or 7.62x39mm) as the defined threat caliber, requirements would be defined by the ‘MEDIUM’ threat level category.[2]

UFC 4-023-07 also provides specifications on the minimum thickness of bullet-resistant fiberglass materials. However, a more reliable approach is to reference the performance data of specific fiberglass products as tested in accordance with industry standards.

Manufactured bullet-resistant products (e.g., doors, glazing, fiberglass panels, armor products, etc.) are normally tested and rated in accordance with several standards including UL 752, ASTM F1233-08, EN 1063, EN 1522, NIJ Standard-0101.06, and SD-STD-01.01.

In the United States, the two most common standards for specifying bullet-resistant building products are UL 752 and ASTM F1233-08. [3][4]

UL 752

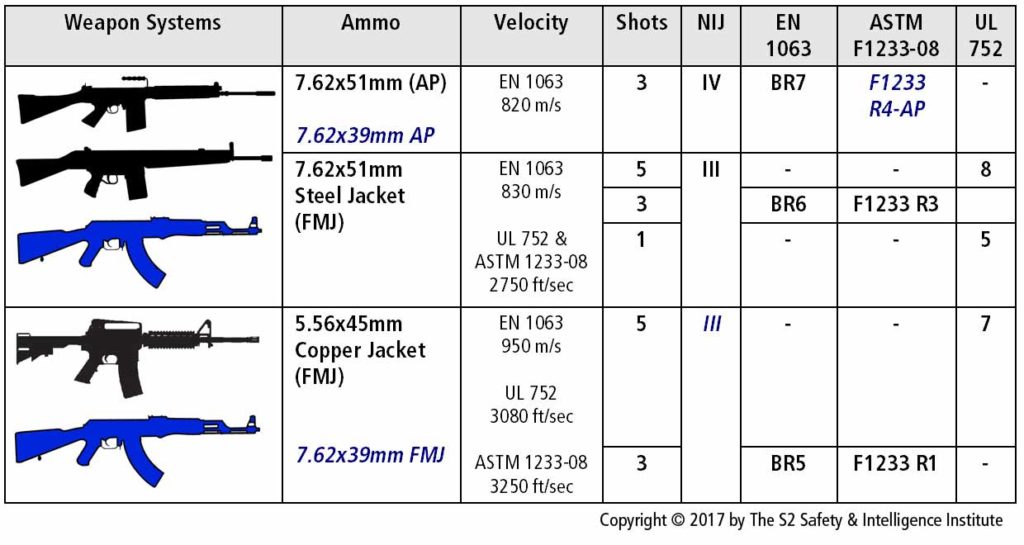

UL 752 describes grades of ballistic resistance using ten levels encompassing weapon calibers ranging from 9mm handgun up to .50 caliber rifle plus an additional level for 12 gauge shotgun. The ammunition and number of shots the specimen resists (1, 3, or 5 shots) defines the Class Threat Level of the product. Under the UL 752 rating system, adequate specifications for protection against military small arms would define UL 752 Level 7 (5.56mm x 5 shots), Level 8 (7.62x51mm x 5 shots), or Level 9 (.30 caliber armor-piercing x 1 shot).

ASTM F1233-08

ASTM F1233-08 uses a scale of eleven Classes/Levels to describe the ballistic resistance of glazing systems. Under the ASTM F1233 rating system, specimens must successfully resist penetration by one or three shots from defined weapon calibers ranging from .38 cal up to .30-06 armor piercing ammunition and 12 gauge shotgun. Under the ASTM F1233 rating system, specifications for protection against military small arms would define F1233 R1 (5.56mm x 3 shots), F1233 R3 (.308 Win./7.62x51mm x 3 shots), or F1233 R4-AP (.30-06 M2-AP x 1 shot).

NIJ Standard-0101.06

In the U.S., bullet-resistant body and vehicle armor are normally tested and classified according to NIJ Standard-0101.06.[5] The NIJ standard uses a six level type classification system to define protection levels. For classification under Types I through III, specimens must resist penetration by five shots according to the standard’s test procedure. Type IV armor products must resist a single shot by .30-06 armor-piercing ammunition. Although NIJ Standard-0101.06 is primarily designed for testing body armor, manufacturers of bullet-resistant building materials often test their products according to the NIJ standard in addition to others. If a security planner uses NIJ Standard-0101.06 for defining protection against military small arms, specifications should state a product classified as Type III (7.62mm x 5 shots) or Type IV.

SD-STD-01.01

All products rated under the U.S. Department of State standard SD-STD-01.01 have been tested against penetration by military small arms and shotguns.[6] The SD-STD-01.01 test procedure involves a minimum of nine shots by 5.56mm, 7.62x51mm, and 12 gauge buckshot in sequence against different target locations.

EN 1063

Outside North America, EN 1063 is one of the most common standards for rating bullet-resistant materials.[7] EN 1063 uses a seven-tiered scale to define ballistic protection from projectile weapons (BR classes) ranging from .22 cal. long rifle to 7.62x51mm hardcore ammunition and two additional levels to define protection against shotguns (SG class). Specimens rated under EN 1063 must resist penetration by three shots according to the standard’s test requirements. Under EN 1063, adequate specifications for protection against military small arms are BR5 (5.56mm), BR6 (7.62x51mm), or BR7 (7.62x51mm hard core).

EN 1522

Another European ballistic resistance standard is EN 1522 for windows, doors, shutters and blinds.[8] EN 1522 uses a seven level classification system to describe ballistic resistance by calibers ranging from .22 cal. long rifle to 7.62x51mm hardcore ammunition, and one additional level for 12/70 shotgun. The procedure described in EN 1522 requires that the specimen is subjected to three shots at various target points which are determined based upon the type of product under evaluation. For the purposes of specifying protection against military small arms, appropriate EN 1522 ratings include FB5 (5.56mm), FB6 (5.56mm and 7.62x51mm), and FB7 (7.62x51mm hard core).

The following table compares several common ballistic resistance standards and ratings applicable for protection against military small arms.

Other standards with potential use in specifying ballistic protection requirements in safe room design include:

- NATO AEP-55 STANAG 4569

- AS/NZS 2343:1997 Standard

Hold up for a moment…We mentioned 5.56mm, 7.62x51mm (NATO), .30-06 cal, and shotgun, but what about the most popular weapon used by terrorists worldwide–the Kalashnikov (7.62x39mm)?

With the exception of NATO’s STANAG 4569 and provisions for specially testing 7.62x39mm in European standards (e.g., EN 1522, etc.), none of the common standards for bullet-resistant products specifically addresses 7.62x39mm as a test caliber. It is safe to assume products successfully rated for protection against 7.62x51mm will be effective in stopping 7.62x39mm. It is well established that 7.62x51mm has better penetration capability than 7.62x39mm. Therefore, any product rated as/or greater than UL 752 Level 8, ASTM F1233 R3, NIJ Type III, EN 1063 BR6, or EN 1522 FB6 will be adequate for protection against 7.62x39mm weapons.

Many product manufacturers also claim that EN 1063 BR5 and UL 752 Level 7 are effective in resisting 7.62x39mm ball ammunition. Although there are significant differences in the ballistic properties of 5.56x45mm and 7.62x39mm ammunition, there are sources which indicate similar penetration capabilities.[9] However, I recommend requesting documented proof from manufacturers of successful 7.62x39mm testing for EN 1063 BR5 and UL 752 Level 7 products before relying on these rating levels.

[1] UFC 4-023-07, Design To Resist Direct Fire Weapons Effects. US Department of Defense, N.p.: 2008.

[2] Ibid. pp. 2-1

[3] UL 752, Standard for Bullet-Resisting Equipment. UL, N.p.: 2005.

[4] ASTM F3038-14, Standard Test Method for Timed Evaluation of Forced-Entry-Resistant Systems, ASTM International, West Conshohocken, PA, 2014

[5] NIJ Standard-0101.06, Ballistic Resistance of Body Armor. U.S. Department of Justice, Office of Justice Programs, National Institute of Justice, Washington, DC, 2008.

[6] SD-STD-01.01, Revision G. Certification Standard. Forced Entry and Ballistic Resistance of Structural Systems. U.S. Department of State, Bureau of Diplomatic Security, Washington, DC, 1993.

[7] EN 1063:2000, Glass in building – Security glazing – Testing and classification of resistance against bullet attack. European Committee for Standardization, Brussels, 2000.

[8] EN 1522:1999, Windows, doors, shutters and blinds. Bullet resistance. Requirements and classification. European Committee for Standardization, Brussels, 1999.

[9] “5.56×45 versus 7.62×39 – Cartridge Comparison.” SWGGUN. SWGGUN, N.p. https://www.swggun.org/5-56-vs-7-62/. Accessed 22 Sept. 2017.

Craig Gundry

Copyright © 2020 by Craig S. Gundry, PSP, cATO, CHS-III

CIS consultants offer a range of services to assist organizations in managing risks of active shooter violence.

Contact us for more information.